Go Further with the Best Trail-Proven ATV Parts

Quick stat: riders adding core protection plus a handful of proven parts often log 2× the safe trail days in a season.

American Off-Roads streamlines buying of U.S.-based, performance-first upgrades that deliver. We curate trusted brands and ship parts nationwide Fuel stroke rims so you can improve throttle response, handling, and service life with confidence.

Common upgrades include cargo bags, LED bar lights, rearview mirrors, hand guards, underbody plates, luggage racks, exhaust and intake components, and bumpers for protection. With routine maintenance, many quads reach 10,000–12,000 miles, and well-cared-for machines can run for 20 years.

Start upgrades with intake, exhaust, and protection that maximize time on trail and minimize risk. Pair power parts with skid plates and bumpers to keep components safe. Keep rider protection in the plan: a helmet, goggles, riding gloves, and over-the-ankle boots keep days fun and safe.

- Lead with performance-minded upgrades for a real improvement every ride.

- Filter by model to prevent mismatches and ensure model-correct parts.

- Combine power add-ons with protection to lower long-term costs.

- Plan installs in stages: bolt-ons first, then larger projects.

- Include basic rider protection to keep trail days safe and enjoyable.

Shop Proven ATV Performance Gear at American Off-Roads

Shop with confidence thanks to transparent fitment, honest specs, and fast U.S. shipping.

Explore a targeted catalog of parts and accessories built for long life and practical gains. Browse products like cargo bags, LED light bars, rearview mirrors, handguards, underbody plates, and luggage racks that riders search for most.

We recommend matching components from top brands and make fitment simple. Filter by machine—Polaris, Can-Am, Honda, Yamaha, Kawasaki, and Arctic Cat—so you only see items that fit your machine.

Product pages show specs, compatibility, and availability up front. That speeds comparison and lets you plan installs around ship dates.

- Streamlined discovery to reduce confusion.

- The catalog spans daily upgrades and specialty add-ons for trails, mud, hunting, and work.

- Occasional sale opportunities and fast shipping keep projects moving.

What Makes American Off-Roads a Smart Choice

Expert guidance, quick delivery, and trusted brands help you finish projects with confidence.

Top brands, real support, and fast U.S. shipping

Choose from a curated lineup of top brands and get clear fitment details before you buy. Our team gives quick answers so you match parts to your goals.

- Expect fast shipping options, often same-day processing for orders placed late afternoon.

- Scan review highlights to learn about installation and real-world performance.

- Spot value choices during sales without sacrificing durability.

Rider-trusted customer support

Our specialists assist before purchase through install. That reduces returns, delays, and surprises.

| Area |

What You Get |

Why it Matters |

| Brands |

Proven fitment and parts specs |

Less guesswork, easier installs |

| Support |

Fast responses, expert tips |

Avoids errors; saves time |

| Shipping |

Fast U.S. delivery and tracking |

Get back on the trail sooner |

Performance-Enhancing ATV Gear

Sort upgrades by impact so you can build upgrades that matter fast.

Kick off with intake/filtration and exhaust to boost throttle feel and enhance airflow. These high-impact parts consistently deliver gains for most riders.

Next, upgrade lighting to see better after dark. LED solutions use less power and throw light farther for better trail visibility.

Guard the chassis using skid plates, A-arm guards, and bumpers. Armor minimizes costly damage so power upgrades last longer.

Looking for added clearance? Lift kits plus spacers enable larger tires and stabilize handling. Pair those changes with brakes and suspension for predictable control.

- Select rider gear that matches how hard you ride, from basic protection to advanced protection.

- Use category pages to compare compatible products and sort by model to reduce risk.

- Watch sale listings to save on combos that blend power, armor, and lighting.

| Area |

Main Benefit |

When to Shop |

| Intake/Filters |

Sharper throttle |

Start here |

| Exhaust Systems |

Improved flow & torque |

Alongside intake |

| Lighting/Armor |

Visibility and protection |

Any time; pair with power |

Quick Power Gains: Intake, Filtration, Exhaust

Intake/exhaust tweaks usually make the biggest difference for daily trail use and chores.

High-flow air intake and filters for immediate gains

Quality filters and high-flow intakes help your engine breathe. That sharpens throttle response and smooths delivery.

American Off-Roads lists fitment by model so you only see parts that fit your atv utv. If you have questions, our team responds with model-correct guidance.

Exhaust Systems for Torque-Focused Builds

Match an exhaust that suits your riding style. Choose systems tuned for low-end torque if you pull heavy loads or favor steep climbs.

Consider full kits that pair intake and exhaust for balanced gains and easier installs. Always check fuel mapping and keep filters clean in dusty conditions.

- High-flow intake/filter combos sharpen throttle and consistent power on varied terrain.

- Choose exhausts balancing torque, tone, and compliance for long rides.

- Pick matched kits for easier installs and predictable performance results.

- Back up gains with good cooling, underbody protection, and routine maintenance.

| Component |

Primary Benefit |

Best Timing |

| Intake |

Better airflow |

First upgrade |

| Air Filter |

Stable delivery |

With intake |

| Exhaust |

Torque and tone |

Post-intake |

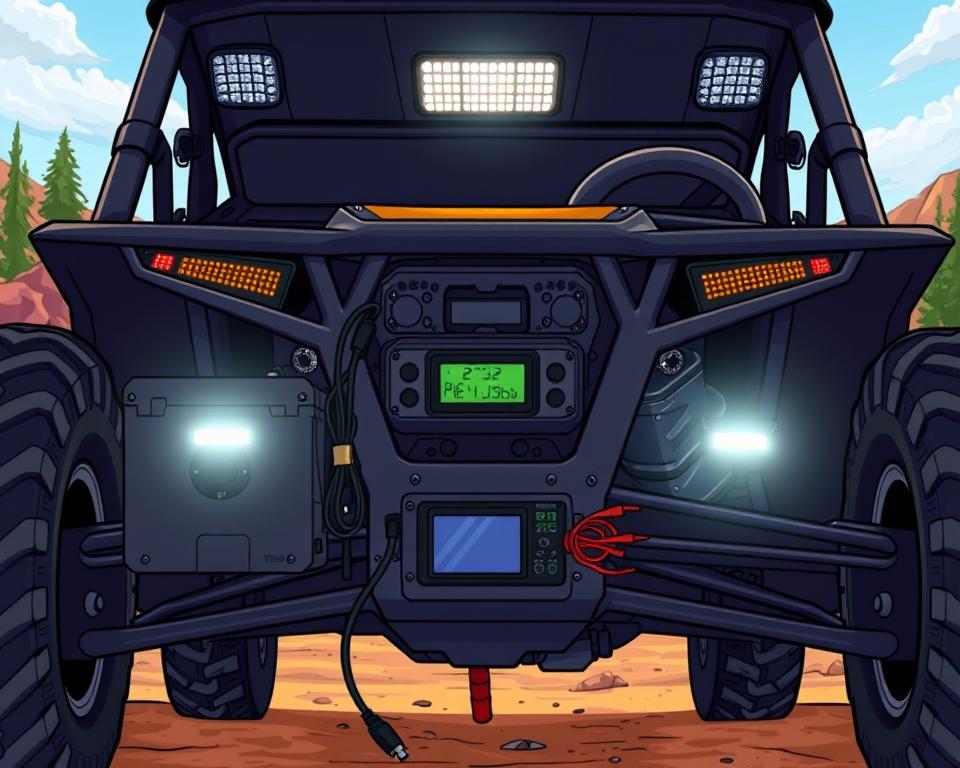

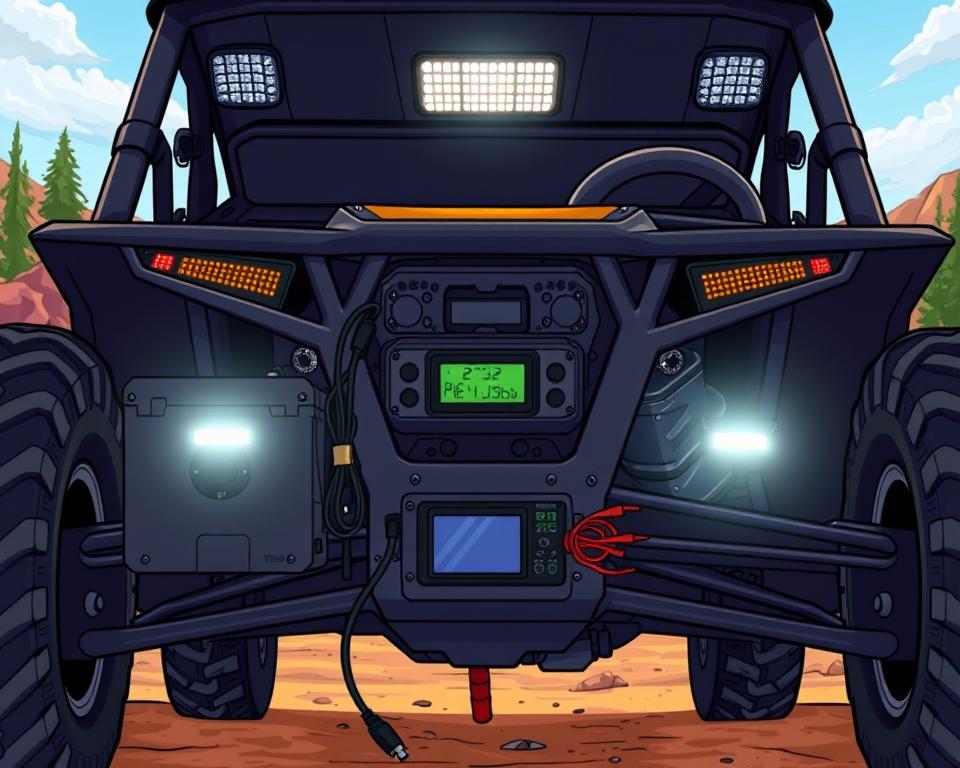

See and Be Seen: LED Light Bars and Lighting Upgrades

A thoughtful lighting setup improves visibility and lowers fatigue.

Choose lighting that fits how and where you ride. American Off-Roads stocks reliable LED bars, compact LED pods, and mounting kits to help you install cleanly. Our team can recommend mounts, harnesses, and fits so your build remains clean and reliable.

LED light bars, pods, and mounting options

Use LED bars for distance and width and pods for tight spots. Mounts vary—front bumper plates, A-arm mounts, and roof brackets are common choices. Place lights to shield lenses from brush and impacts.

Night riding on trails: brighter beams, safer rides

Match beams to terrain: spot = distance, flood for close spread, combo = mixed routes. Right lighting sharpens reaction time and reduces rider fatigue on long night runs.

LED Install & Wiring Basics

Verify amp draw, use a wiring harness with a relay, and use weatherproof connectors. Route cables away from pinch points and keep spare fuses in your tool kit. Verify local rules for auxiliary lighting.

- Choose efficient light bars and compact pods to limit current draw.

- Evaluate spot, flood, and combo beams for your common terrain.

- Pair lights with mirrors and skid plates for better situational awareness.

- Watch for sale bundles that include bars + mounts + harnesses.

| Option |

Ideal Use |

Typical Feature |

| Full-length bars |

Fast, open trails |

Long throw spot or combo beams |

| LED pods |

Tight technical sections |

Wide flood patterns, low draw |

| Mount kits & harnesses |

Clean installs across models |

Relay harness, sealed connectors, fuse holders |

Protect the Machine: Skids, A-Arm Guards, Bumpers

Proper armor builds confidence on rocks and overgrown trails.

American Off-Roads can help you choose armor and bumpers that fit your machine and the terrain you ride most. Riders often report major durability gains after installing full underbody kits and A-arm guards.

Full-Coverage Skids for Rough Terrain

Choose full-coverage plate kits to protect frame, diffs, and mounts. Look for recessed hardware and formed edges so the plates slide over rocks rather than snagging.

Brush guards and bumpers for impact protection

Install front/rear bumpers to deflect brush and cushion slow impacts. Combine bumpers with A-arm guards and sliders for the broadest coverage.

- Armor acts like insurance: skid plates and A-arm guards shield vital parts from rocks and ruts.

- Consider UHMW for light weight or aluminum for durability based on terrain.

- Verify fitment, re-torque after shakedown, and add handguards.

| Item |

Benefit |

Best Use |

| Underbody plates |

Frame and differential protection |

Rocky terrain |

| A-arm protection |

Preserve suspension components |

Technical routes |

| Bumpers |

Brush/impact defense |

Brushy and low-speed obstacles |

Get the Stance and Clearance You Need: Lift Kits and Wheel Spacers

A small lift with well-matched spacers can change how you move through ruts and rocks.

Lift kits plus spacers raise clearance and widen track so your vehicle clears obstacles more cleanly. American Off-Roads offers kits and spacers curated for reliable fitment across Polaris, Can-Am, Honda, Yamaha, CFMoto, and more.

Lifts for Tire Room & Belly Clearance

Lift kits create tire clearance and belly room so your vehicle skims ruts instead of high-centering.

Quality kits come with clear instructions and hardware, making weekend installs realistic with common tools. After install, check torque specs after a few rides since fasteners may settle.

Wheel Spacers for a Planted Ride

Wheel spacers widen track width for a planted ride, improving confidence in off-camber sections and technical climbs.

Match spacer thickness/lift height to tire size to preserve steering feel and CV angles. Consider firmer damping if wider stance or taller tires add leverage.

- Combine lifts with skid upgrades to maintain skid coverage at new height.

- Verify atv utv fitment for year/trim to avoid geometry surprises.

- For towing/hauling, balance lift goals with stability/braking.

| Upgrade |

Benefit |

When to Fit |

| Lift kits |

Extra clearance for bigger tires |

When you need belly room |

| Spacers |

Wider stance, better stability |

For off-camber/technical routes |

| Complete kits |

Matched fitment and hardware |

Weekend installs with common tools |

Handling & Comfort: Suspension and Add-Ons

Good suspension tuning plus cockpit tweaks reduce fatigue on long rides.

Suspension tuning is the fastest way to improve control and comfort, especially after adding weight or bigger tires. Pick shock kits/springs matched to your terrain and load—solo, two-up, or with cargo.

Add seat cushions, bar risers, and handguards to cut fatigue and keep confident steering inputs. Small changes maintain posture and lessen arm pump.

- Adjust damping up or down to fit speed and surface so tires stay planted for traction and braking.

- Blend small-bump comfort with bottom-out control for a balanced, predictable feel.

- Check shock rebuild intervals and bushings regularly to keep handling crisp.

| Upgrade |

Main Benefit |

When to Use |

Tip |

| Shock packages |

Improved control/damping |

Post weight/tire changes |

Pick valving for your terrain |

| Seat pads |

Lower fatigue |

All-day sessions |

Seek gel/absorbing foam |

| Risers & hand guards |

Improved posture and protection |

Technical riding |

Lowers arm pump and shields hands |

| Tire setup |

Traction and compliance |

With suspension tuning |

Tune PSI and sidewall |

We help select kits/parts that match your goals without overspending on features you won’t use. A comfortable cockpit boosts confidence and supports your riding style.

ATV Safety Gear Essentials

A smart kit of protective apparel keeps you safer and more confident on every trail.

Every rider should start with a DOT-approved helmet, clear/tinted goggles, protective gloves, and sturdy boots. This basic set is the baseline of safer riding.

For faster trails or racing, add a chest guard, kidney support, and knee braces. These pieces reduce impact forces and protect soft tissue during high-speed incidents.

Helmet, goggles, gloves, boots: dress for the crash

Pick a snug-fit helmet and carry proper certification. Swap liners/pads as they wear to maintain protection.

Pick goggles that seal well and stay clear. A spare pair of gloves and dry socks in your storage bag increase comfort on long rides.

Torso & Knee Protection for Speed

Wear chest/kidney protection under jerseys for airflow plus impact resistance. Knee braces help prevent hyperextension on technical sections.

Pants, jerseys, and gloves combos

Choose breathable, durable pants/jerseys. Glove-matched bundles simplify shopping and often save money.

- Dress for the crash with a certified helmet, goggles, hand protection, and boots.

- Add chest/knee/kidney protection as speeds rise.

- Select breathable apparel that resist tears and wick moisture.

- Favor high-visibility accents and reflective elements for low-light rides.

- Fit is crucial—correct sizing lowers fatigue and helps control.

| Gear |

Benefit |

When to Use |

| Helmet |

Protects head |

Every ride |

| Torso protection |

Impact & torso shielding |

High-speed or aggressive |

| Pants & Jersey |

Comfort + abrasion resistance |

All-day rides |

American Off-Roads encourages prioritizing protective gear that fits speed, terrain, and skill.

Fitment by Brand: Polaris, Can-Am, Honda, Yamaha, Kawasaki, Arctic Cat, CFMoto

Find parts that fit your quad or ATV/UTV

Use brand filters to surface parts fast that match your model and trim. Picking make, year, and specific vehicle up front cuts returns and reduces guesswork.

Model-Correct Parts Only

We organize a wide selection so you only see compatible options for Polaris, Can-Am, Honda, Yamaha, Kawasaki, arctic cat, and CFMoto. That means fewer surprises at the bench and faster installs.

- Filter by make/model to see only compatible parts your vehicle and bolt pattern.

- Browse selection atv categories: power, protection, lighting, storage to speed up planning.

- Pick armor matched to frame geometry with quad-specific skids and A-arm guards.

- Use reviews for real-world tips from riders who installed the same parts.

- Verify electrical connectors and fastener specs to avoid mid-install surprises.

- Filter by use case if you ride work + play to choose value-first parts.

- For Arctic Cat and less-common trims, compatible pieces are clearly flagged so you avoid guessing.

- If a clearance item fits, it’s a smart way to save on essentials you already intended to buy.

| Area |

Why It Matters |

What to Check |

| Fitment filters |

Only see parts that match your vehicle |

Year, model, trim |

| Armor |

Armor tailored to frame |

Skid thickness & coverage |

| Reviews/Clearance |

Real feedback and savings |

Install notes/photos |

Unsure about cross-year fit?, reach out—our team will check fit and help you pick the right parts fast.

Trail, Work, Hunt, or Race: Gear by How You Ride

Pick accessories that match how you ride so every outing is more capable and comfortable.

Trail riders often add LED light bars, a shock-absorbing seat cushion, handguards, and a GPS mount for long runs. These items improve visibility, reduce fatigue, and keep navigation simple.

Work-focused builds lean toward cargo racks, storage boxes, mirrors, and wind protection. Those pieces reduce downtime and ease chores for ranch and utility tasks.

Hunters value quiet exhaust options, low-profile finishes, and secure weapon or gear mounts. Low-viz colors and sound control help you stay undetected in rough terrain.

Racing or fast riding calls for stronger armor, improved cooling, and advanced protective apparel. Focus first on brakes, tires, and cooling to keep pace controlled.

- Choose pants and jerseys for climate: breathable fabrics for heat, insulated for cold starts.

- Balance spend: start with high-impact accessories, then add the rest over time.

- Mix visibility gear with low-light lighting if you often start at dawn or return at dusk.

- For family rides, prioritize comfort and communication accessories to keep everyone enjoying the day.

| Riding Style |

Top Picks |

Why It Matters |

| Trail |

Lights, seat cushion, handguards |

Comfort + night sight |

| Utility |

Racks/storage/mirrors |

Efficiency and reduced fatigue |

| Hunt |

Quiet exhaust + stealth mounts |

Lower detection, secure gear |

| Speed |

Armor/cooling/brakes |

Durability and control at speed |

American Off-Roads recommends style-based bundles to simplify checkout and make sure your build matches the way you ride.

Shop by Category: Power/Protection/Lighting/Storage/Mirrors

Navigate by purpose—power, protection, lighting, or cargo—to build a trail-ready setup quickly.

American Off-Roads lays out clear categories so you can shop confidently. Categories group power, armor, lighting, storage for complete solutions.

Pick storage bags and racks that secure tools and gear without rattling. Use proper mounts/hardware for clean installs across atv utv models.

Mirrors, windshields, and handguards

Add mirrors/windshields to boost comfort and awareness on long days. Handguards protect controls and hands from brush and debris.

- Explore power categories first—intake, filters, exhaust—then layer protection + lighting.

- Lighting runs from compact pods to LED bars that throw light far down the trail.

- Shop lift kits to fit larger tires and confirm cable slack before riding.

- Skids and A-arm plates protect critical parts and pair nicely with rock sliders.

- Watch sale tags in each category when building multiple systems.

| Group |

Benefit |

Common Parts |

| Power Adders |

More throttle/torque |

Intake, filters, exhaust |

| Armor |

Durability on trails |

Skids, guards, bumpers |

| Lighting & Storage |

Sight + cargo |

LEDs, bars, racks |

Deals & Clearance at American Off-Roads

Deal filters and search help riders pair savings with fitment for confident buys.

Sale and clearance filters to save on kits and parts

Use price filters to find the best value components without overpaying. Filter by sale and clearance to surface last-chance sizes, model-specific gear, seasonal promos.

Scan reviews before you commit so a low price still meets your needs. Look for discounts on light, helmet, gloves, and boots to refresh PPE while upgrading the machine.

- Use price ranges to narrow parts by your budget and skip unneeded features.

- Check clearance for model-specific plates and skid pieces that can save you significantly.

- Spot sale bundles that pair kits and components for better value together.

- Confirm atv utv compatibility to avoid fitment headaches when shopping deals.

- Combine sale and clearance filters and time purchases to hit free shipping thresholds when available.

| Filter |

Benefit |

Use When |

| Price range |

Fast best-value scan |

Fixed budget |

| Closeout |

Last-chance savings on specific models |

When fitment matches |

| Promotions |

Seasonal bundles and marked-down kits |

Multi-system builds |

Shipping & Delivery: Fast, Tracked, and Often Free

Quick U.S. delivery with tracking make the cart-to-garage jump confident.

Plan your order to meet published free shipping thresholds so essentials arrive in time for weekend installs. Many orders placed by late afternoon ship the same day, which accelerates projects when you need parts quickly.

Clear ETAs and tracking keep timing predictable. Estimates reflect inventory, so you can prep tools/workspace confidently.

On deadlines (event/trip), our support can suggest best ship options/route. For oversized boxes, check shipping notes so you can plan an extra set of hands at delivery.

Combine sale and clearance items with in-stock essentials to reach free-shipping without overspend. We pack securely to protect vehicle parts in transit and minimize damage risk.

- Hit free shipping minimums by combining in-stock items with sale finds.

- Use tracking updates to schedule installs and avoid missed deliveries.

- Contact customer service for special delivery instructions or timing needs.

| Service |

Value |

Use Case |

| Same-day handling |

Faster weekend arrivals |

Late-afternoon orders |

| Free shipping thresholds |

Lower overall cost |

Combine deals + essentials |

| Delivery notes & packaging |

Transit protection |

Large or fragile items |

Reviews that Reflect Real-World Use

Verified reviews help you spot parts that deliver handling gains, brighter light, and lasting fit.

Lean on review details to check fitment accuracy and installation time before you buy. Many riders praise precise fit and fast shipping, which reduces delays.

Wheel spacers and lift kits often get calls for improved stability and handling right after install. Lighting upgrades—LED bars and compact pods are praised for beam distance and pattern clarity in dusty/wet conditions.

Safety gear remains a top recommendation. Customer notes on helmet, gloves, and boots help you find options that balance protection, airflow, and comfort.

| Topic |

Praise |

Check |

| Fit |

Right pattern; easy install |

Model year and trim compatibility |

| Handling |

Stance + suspension feel |

Spacer thickness, shock valving |

| Lighting |

Distance + durability |

Mount type and amperage draw |

| Safety kit |

Comfort + protection |

Sizing; cert; venting |

Let repeated praise guide you to reliable parts. If unsure, ask our team for top-reviewed, model-matched picks.

Bundle and Save: Kits Curated for Trails, Mud, and All-Day Rides

Build a cohesive setup quickly. Smart bundles pair compatible components so your project finishes faster and fits right on the first try.

American Off-Roads curates bundles that group lighting, protection, and mounting hardware. These products arrive install-ready with clear contents lists and compatibility notes.

Bundling reduces the overall price and cuts parts-hunting time. When items share hardware and fitment, installs go smoother and returns decrease.

- Trail bundles: lighting + handguards + skid for all-day confidence.

- Mud kits bundle lifts, extended protection, and mounts for deep ruts.

- Armor bundles: skids + A-arm guards + sliders so coverage works system-wide.

- Bundles are tailored to atv utv platforms where possible to speed fitment and instructions.

| Bundle Type |

Contents |

Best For |

| Trail Kit |

LED light, handguards, skid plate |

All-day mixed terrain |

| Mud bundle |

Lift + extended skid + mounts |

Deep mud/ruts |

| Armor bundle |

Full skids + A-arm + sliders |

Rocky/technical |

| Custom Kit |

By-request matched parts + hardware |

Custom goals/schedules |

Watch sale windows to maximize value. If you want a custom kit, reach out—we’ll help you build a package that fits your terrain and schedule.

Pick the Right Accessories for Your ATV/UTV

Start with terrain; finish with verified fitment.

Align your goals to the parts you buy: trail use wants lighting + comfort, mud runs demand clearance and durable protection, and work rigs want racks and storage. Begin with safety/comfort essentials, then layer in power and protection.

Safety comes first. A certified helmet, goggles, gloves, and boots are the foundation. Add chest guards or braces if you ride fast or tackle technical lines.

Fast Decision Guide

- Define your terrain: trail/mud/work/hunt, then pick matching parts.

- Verify suspension/payload before adding heavy parts.

- Begin power with intake/exhaust to add reliable gains.

- Balance spending across protection, lighting, and comfort no matter whether ‘re new or seasoned riders.

- Track maintenance; time expensive buys with sales; save pants and jersey refreshes for promos.

- When unsure, contact customer support for model-specific recommendations.

| Area |

First Step |

Why It Matters |

| PPE |

Helmet, goggles, gloves, boots |

Safety foundation for upgrades |

| Performance |

Intake + exhaust |

Improves throttle without heavy reliability trade-offs |

| Fitment |

Select model-correct atv parts |

Fewer returns; faster installs |

Install Made Easier: Fit Guides, Simple Upgrades, and Support

Simple, well-documented installs make upgrades less intimidating and get you back on trail faster.

Fast upgrades like pegs, mirrors, and LED lights add notable comfort/safety with minimal tools.

American Off-Roads offers clear fit guides so you can shop with confidence and avoid returns. Each product page lists years/trims plus tool/torque notes.

Most lighting/armor installs fit a weekend using basic tools. Labeled/organized hardware reduces guesswork.

- Begin with mirrors/pegs/lights to build skills.

- Keep dielectric grease, threadlocker, and a torque wrench handy for longer-lasting results.

- If you hit a snag, our customer service can troubleshoot with tips from real installs.

| Step |

What to Expect |

Time |

| Fitment check |

Check Y/M fit + bolt pattern |

~5–10 min |

| Prep hardware |

Labeled packs and instruction highlights |

~10–20 min |

| Install phase |

Basic tools, torque specs noted |

30–120 minutes |

| Post-install check |

Check clearance/alignment/aim |

5–15 minutes |

In Closing

Finish your list with items that make an immediate difference on ride day. Pick proven upgrades for protection, a bright light, and steady performance so your first run after install feels better right away.

Watch price closely and use sale and clearance windows to extend your budget. Combine items to hit free-ship thresholds and lower overall cost.

Balance kits and single parts to match your time and skill. Don’t forget safety: a quality helmet/gloves/boots keep gains useful and riders confident.

Need help? Reach out for fitment checks, shipping options, or kit recommendations. Our team and selection are here to help you finish smart so you ride more with less worry.